Glaze Coat Epoxy Dry Time

If it s colder than that the resin will be thicker and harder to mix will have more bubbles and will take longer to cure until it s dry to the touch.

Glaze coat epoxy dry time. Amazing goop hardens by solvent evaporation so allow time for thorough hardening to ensure proper bonding and wear resistance. Enough for three rv sized countertops. Glaze coat is heat resistant to approximately 120 f 49 c after fully cured. This ultra clear high gloss finishing epoxy is ideal for home improvement and craft projects.

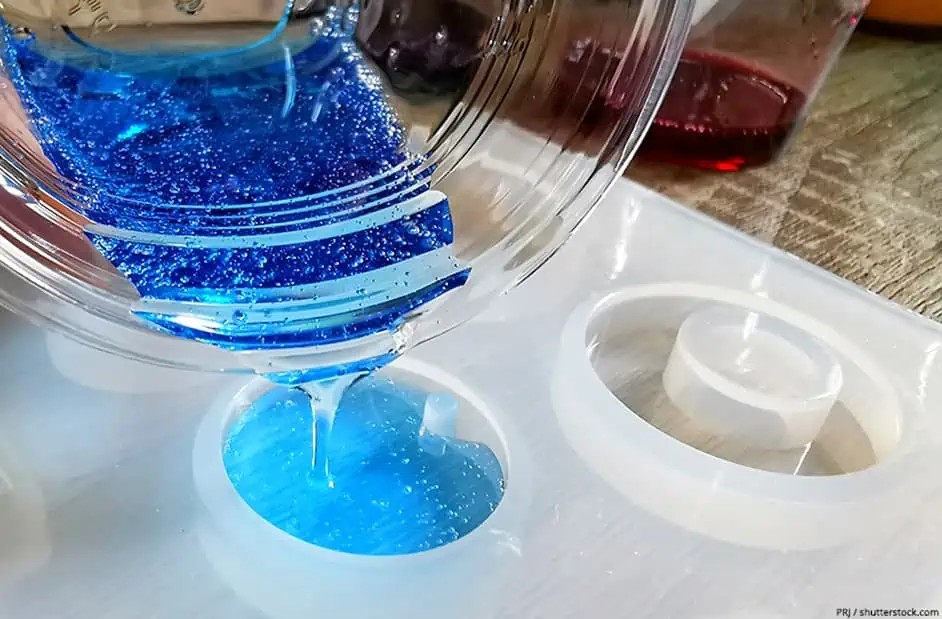

In 12 to 15 hours. Just one coat equals 70 coats of. It s great for coating tables or bar tops preserving photographs or imbedding decorative items. Famowood glaze coat is a pour on epoxy coating.

Use thin coats of amazing goop to build a thick coating on the surface to be sealed allowing each layer to set 3 to 4 hours. Here s how to do it. Buy now click here. Finally you ll simply wait around for your epoxy to cure harden and dry.

By the time we were done with one seal coat the 2 quarts of mixed epoxy had already hardened in the bucket and was useless. Famowood glaze coat is a pour on epoxy coating that can be used on most surfaces rough or smooth stained or painted. Weight gallon clear 450 psi. The first batch we mixed for the seal coat was a large amount of mixture.

Glaze coat is great for coating tables bar tops preserving pictures and photographs or imbedding items such as coins or rocks. Warmer temps accelerate cure time and colder temperatures slow down cure time. You may want to add a second coat. This is especially ideal for smooth surfaces such as plastic glass or ceramic.

This ultra clear high gloss finishing epoxy is ideal for home improvement and craft projects. Glaze coat famowood wood filler seal all adhesive quickhold adhesive e6000 adhesive e6100 non sag adhesive e6800 uv resistant self leveling glue all purpose adhesive mend vacuum cleaner attachments seal worn or cracked water hoses repair broken ceramic flowerpots marine epoxy paste goop super mend automotive epoxy paste. Working time tack free time. Not knowing what we were doing it took us longer to apply the seal coat on the first time.

From time to time it may be necessary to add a second coat to your resin job. It is ideal to go ahead and give your epoxy 24 hours before really using it just to ensure it is 100 ready to go. Just one coat equals 60 coats of varnish. Place some type of protection such as coasters or hot pads when placing hot objects on glaze coat surfaces.

The ideal room temperature for mixing artresin epoxy resin is between 75 and 85 degrees f or 24 30 degrees c. Famowood glaze coat is recommended for interior use only and should not be used on hot surfaces such as ash trays or cookware. Typically this takes a little bit longer with the second coat than the first.